W24 Profile Bending Machine Introduction

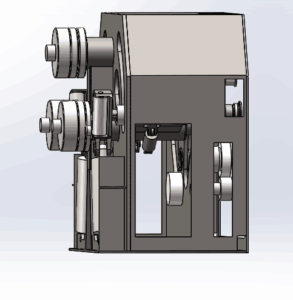

W24 profile bending machine is a curved three rolls profile bending machine with pre bending function for profiles. It mainly consists of the bed body, edge roller, support roller, transmission part, electrical part, hydraulic system, mold, etc.

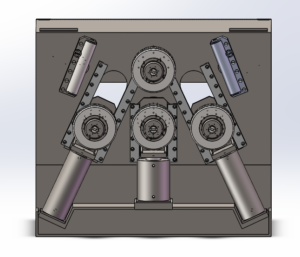

The three roller shafts of the machine are all the main driving rollers, which are achieved through hydraulic motors and gears. The lifting of the two side roller shafts is hydraulic transmission, and the two roller shafts can move in an arc around the fixed rotation center. There are support rollers and correction guide roller devices on both sides of the working roller.

The straightening roller of this machine has three movements:

(1) It can perform lifting and lowering movements

(2) It can perform curved lifting motion with both rollers simultaneously

(3) It can perform rotational motion simultaneously to ensure the forming quality of the profile during the rolling process.

The lifting displacement of the two side roller shafts is displayed digitally, which is eye-catching and intuitive. The W24 profile bending machine is equipped with an independent operating platform, making it easy to operate. The bed of the machine is made of welded steel plates and has undergone annealing treatment to eliminate internal stress.

The whole profile bending machine has sufficient strength and stiffness to meet the bending of profiles within the machine’s capacity range. Changing the mold can roll and bend profiles such as angle steel, flat steel, square steel, channel steel, I-beams, round steel, and steel pipes. This W24 profile bendingmachine has an advanced structure, reliable operation, small volume, and complete functions, making it an advanced profile-forming equipment at home and abroad. Widely used in industries such as boilers, shipbuilding, hydropower, and metal structures.

Features

Frame-type heavy-duty welding machine bed: undergoes strict annealing and stress relief treatment to ensure machine stability and accuracy.

42CrMo alloy steel material: The mold is made of high-quality 42CrMo alloy steel forgings. After quenching and tempering treatment and surface quenching, it has excellent mechanical properties and wear resistance.

Full-drive system: The three rollers are all main drive rollers, which prevents slipping when rolling small-diameter profile workpieces and expands the use range of the machine.

Comes with self-correcting side roller device: used for correction of profiles to ensure the molding quality during the rolling process.

High-end full-drive four-axis profile bending machine: Through CNC control, smaller pre-bent straight edge sections can be achieved, saving material. The automatic rolling function enables high-efficiency production.

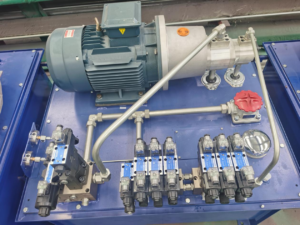

High-standard hydraulic system: Use Yuci Oil Research products and cast flow channel design to ensure reliable system performance. It is also equipped with multiple safety protection devices to ensure safe operation of the equipment.

Technical Parameter

- Mold material: 42CrMo alloy steel forging, quenching and tempering treatment HB240~280, surface quenching treatment.

- Driving method: hydraulic motor and gear drive.

- Types of profiles: angle steel, flat steel, square steel, channel steel, I-beam, round steel, steel pipe, etc. can be rolled.

- Lathe bed structure: Welded structure, which has undergone stress aging treatment to eliminate internal stress and improve accuracy.

| W24- Profile Bending Machine Technical Parameter | |||||||||||||

| Model | 6 | 16 | 30 | 45 | 75 | 100 | 140 | 180 | 260 | 320 | 400 | 500 | |

| Max sector module of Elasticity(cm3) | 6 | 16 | 30 | 45 | 75 | 100 | 140 | 180 | 260 | 320 | 400 | 500 | |

| Rolling Speed (m/min) | 6 | 6 | 6 | 6 | 5 | 5 | 5 | 4 | 4 | 4 | 4 | 4 | |

| Profile Yield Limit (Mpa) | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | 245 | |

|

Max section of Angle Bending | 40×5 | 70×8 | 80×8 | 90×10 | 100×10 | 120×12 | 140×16 | 150×16 | 160×16 | 180×14 | 200×18 | 200×20 |

| Min bending dia. | 800 | 1000 | 1200 | 1500 | 2000 | 2400 | 2500 | 2600 | 2600 | 3600 | 3600 | 4000 | |

| Max section of Angle Bending | 50×5 | 80×8 | 90×10 | 100×10 | 120×12 | 140×16 | 150×16 | 160×16 | 180×14 | 200×18 | 200×24 | 250×25 | |

| Min bending dia. | 800 | 1000 | 1100 | 1300 | 1600 | 1800 | 2200 | 2000 | 2500 | 3600 | 3600 | 4000 | |

| Max section of C-channel Bending | 8# | 12# | 16# | 20# | 25# | 28# | 30# | 32# | 36# | 40# | 45# | 50# | |

| Min bending dia. | 600 | 800 | 800 | 1000 | 1100 | 1700 | 1200 | 1500 | 1800 | 2000 | 2000 | 2400 | |

| Max section of C-channel Bending | 8# | 12# | 16# | 20# | 25# | 28# | 30# | 32# | 36# | 40# | 45# | 50# | |

| Min bending dia. | 700 | 900 | 1000 | 1150 | 1600 | 1700 | 1700 | 1800 | 1800 | 2000 | 2000 | 2000 | |

| Max section of Bending Flat Bar | 100×18 | 150×25 | 180×25 | 200×30 | 220×40 | 250×40 | 280×50 | 300×50 | 330×50 | 360×60 | 400×75 | 500×76 | |

| Min bending dia. | 600 | 700 | 800 | 900 | 1000 | 1200 | 1300 | 1500 | 1900 | 2000 | 2400 | 2400 | |

| Max section of Bending Flat Bar | 50×12 | 75×16 | 90×20 | 100×25 | 110×40 | 120×40 | 150×40 | 180×30 | 190×40 | 190×50 | 200×50 | 200×60 | |

| Min bending dia. | 500 | 760 | 800 | 1000 | 1100 | 1300 | 1500 | 2000 | 2000 | 2400 | 2200 | 2500 | |

| Max section of Bending Pipe | 42×4 | 76×4.5 | 89×5 | 89×8 | 114×5 | 159×5 | 168×6 | 168×8 | 219×8 | 245×8 | 273×8 | 323×10 | |

| Min bending dia. | 500 | 750 | 900 | 900 | 1200 | 2000 | 2000 | 2000 | 3500 | 3000 | 3500 | 4200 | |

| Max section of Bending Round Steel | 38 | 52 | 62 | 75 | 85 | 90 | 100 | 110 | 120 | 135 | 150 | 160 | |

| Min bending dia. | 450 | 600 | 600 | 800 | 1000 | 1100 | 1200 | 1300 | 1350 | 1800 | 2000 | 2000 | |

| Max section of Bending Square | 45×3 | 60×4 | 70×4 | 80×6 | 90×8 | 100×10 | 125×10 | 140×10 | 150×10 | 165×10 | 180×12 | 200×12 | |

| Min bending dia | 750 | 900 | 1000 | 1200 | 1600 | 2000 | 2500 | 3000 | 3000 | 3500 | 3500 | 5000 | |

|

Max section | / | / | / | / | 10# | 12.6# | 14# | 16# | 18# | 20.6# | 22.6# | 25.6# |

| Min bending dia | / | / | / | / | 2000 | 2500 | 3000 | 3500 | 4000 | 5000 | 8000 | 10000 | |

W24 Profile Bending Machine Details

The W24 profile bending machine is an advanced profile forming equipment, which mainly consists of a bed part, a side roller part, a roller part, a transmission part, an electrical part, a hydraulic system, a mold, etc.

The machine adopts a frame-type heavy-duty welding bed, which has undergone strict annealing and stress relief treatment. It has sufficient strength and stiffness to meet the profile bending within the machine’s capabilities.

During the rolling process of profiles, the three rollers are all main drive rollers, driven by hydraulic motors and gears, ensuring the stability and accuracy of the rolled workpieces.

The side roller part is equipped with a self-correcting side roller device, which can correct the profile and ensure molding quality during the rolling process.The roller part has three movements: lifting movement, arc lifting movement and rotating movement to ensure the stability and accuracy of the profile during the rolling process.In addition, the hydraulic system uses Yuci Oil Research products and the cast flow channel design ensures the reliability of the system. It is also equipped with multiple safety protection devices to ensure the safe operation of the equipment.

W24 Profile Bending Machine Applications

- Boiler manufacturing: The W24 model profile bending machine is widely used in the field of boiler manufacturing to manufacture various profile components of boilers, such as angle steel, flat steel, etc. Through the rolling of this machine, the structural strength and precision requirements of the boiler can be guaranteed, and the production efficiency and product quality can be improved.

- Shipbuilding industry: In the shipbuilding industry, the W24 profile bending machine is used to manufacture various profile components of the ship hull, such as channel steel, I-beam, etc. Through the rolling of this machine, the firmness and sealing of the hull structure can be ensured, meeting the design requirements of the ship, and improving shipbuilding efficiency and cost-effectiveness.

- Hydropower project: In hydropower projects, the W24 profile bending machine is used to manufacture various profile components for hydropower equipment, such as round steel, steel pipes, etc. Through the rolling of this machine, the stability and durability of hydropower equipment can be ensured, and the safe operation of hydropower projects can be ensured.

- Metal structure building: The W24 model profile bending machine is also widely used in the field of metal structure construction to manufacture various profile components for building structures, such as square steel, round steel, etc. Through the rolling of this machine, the design requirements of the building structure can be met, and the construction efficiency and quality of the construction project are improved.