Introduction

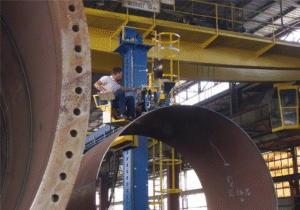

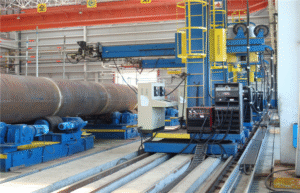

Pronjas introduces the Welding Center series of cross welders, including circumferential cross welders and straight cross welders, designed to meet the welding needs of different sizes. With excellent performance, stable operation, and high adaptability, this series of welders are widely used in various welding applications, providing powerful welding solutions for industrial production.

Features of Cross Welding Machine Welding Center

Multiple models: Heavy-duty, medium-duty and light-duty models are available to accommodate different weight classes of welding tasks.

Effective Stroke: Vertical arm and lateral arm stroke ranges from 2000mm to 8000mm to meet the needs of different diameter welding.

Wide range of applicable diameters: Depending on the model, it is suitable for cylindrical workpieces with diameters ranging from 1000mm to 8000mm.

Swivel angle: The vertical arm provides a ±180°swivel angle and some models support manual adjustment.

Speed Adjustment: The up and down speed and telescopic speed of the horizontal arm are adjustable to adapt to the fast welding operation.

Cart track center distance: provide different lengths of track center distance to adapt to different sizes of welding platforms.

Parameters

| Type | Heavy-duty | Middle-duty | Light-duty | |||

| 8×6 | 5×6 | 4×5 | 3.5×5 | 4×5 | 2×2 | |

| Effective stroke of the vertical boom(mm) | 8000 | 5000 | 4000 | 3500 | 3000 | 2000 |

| Effective stroke of the cross boom(mm) | 6000 | 6000 | 5000 | 5000 | 4000 | 2000 |

| The suitable diameter of the cylinder(mm) | 1000-8000 | 1000-5000 | 1000-4000 | 700-3500 | 700-3000 | 500-2000 |

| Rotating angle of the vertical boom | ±180° | ±180° | ±180° | ±180 | ±180° | ±180°(manual) |

| Up and down speed of cross boom(m/min) | 0.9 | 1 | 1 | 1 | 1 | 0.3 |

| Expansion speed of cross boom(m/min) | 0.12-1.2 | 0.12-1.2 | 0.12-1.2 | 0.12-1.2 | 0.12-1.2 | 0.12-1.2 |

| Forward and backward speed of the trolley (m/min) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| The center distance of the trolley track(mm) | 2308 | 1780 | 1780 | 1780 | 1500 | 900 |

Applications of Cross Welding Machine Welding Center

- Pronjas’ Welding Center series cross welders are suitable for the following applications:

- Pressure vessel manufacturing: for automatic welding of large pressure vessels.

- Pipeline welding: for straight and ring seam welding of long-distance pipelines.

- Heavy Machinery Welding: For precision welding of large workpieces in heavy machinery manufacturing.

- Petrochemical equipment: In the petrochemical industry, for welding of vessels, reactors and other equipment.