Introduction: The importance of profile bending machine and the key to selection.

Profile bending machine plays a vital role in the field of metal processing. It is the key equipment for curling metal profiles and is widely used in machinery manufacturing, construction, automobiles, ships and many other industries. Choosing the right profile bending machine manufacturer is just like choosing a reliable partner for the production activities of an enterprise, which is directly related to product quality, production efficiency and economic benefits of the enterprise. In today’s competitive market environment, how to choose the one that suits you best from many manufacturers of profile bending machines has become an important issue for many enterprises. This article will give you a detailed introduction to the methods and key points of selecting suitable profile bending machine manufacturers to help you make wise decisions.

Clarify your own requirements: determine the specifications and requirements of profile bending machine.

Processing material and thickness:Different metal materials and profile thicknesses have great differences on the performance requirements of the machine à plier les profilés. For example, the pressure and accuracy of the profile bending machine required for processing stainless steel profiles and ordinary carbon steel profiles may be different. If thick metal profiles are often processed, it is necessary to choose a profile bending machine with greater rolling force and stronger structure to ensure that the processing task can be successfully completed, while ensuring product quality and equipment safety.

Requirements for coiling accuracy: For some industries that require high product accuracy, such as aerospace and precision instrument manufacturing, it is necessary to choose high-precision metal profile bending machine. High-precision profile bending machine can accurately control the parameters such as curl radius, angle and straightness of profile, so as to produce products that meet strict quality standards. For some general processing industries with relatively low precision requirements, equipment with higher cost performance can be selected according to the actual situation.

Production scale and efficiency: The production scale and efficiency requirements of enterprises are also important factors in selecting profile bending machines. If it is a large-scale production enterprise, it is necessary to choose a profile bending machine with high automation and high production efficiency, such as a fully automatic numerical control profile bending machine, to meet the production demand of a large number of orders. For small processing enterprises or individual workshops, manual or semi-automatic profile bending machine may be able to meet the production requirements and reduce the equipment procurement cost.

Investigate the reputation and reputation of manufacturers: reputation in the industry is very important.

Customer evaluation and feedback: Search other customers’ evaluation and feedback on the manufacturer through the Internet, industry forums, social media and other channels. Understand their performance in product quality, delivery time and after-sales service. If most customers give high praise to this manufacturer, then this manufacturer is usually a more reliable choice. For example, you can check the experience and evaluation of other users on different profile bending machine manufacturers in the related section of Baidu Post Bar.

Industry status and qualification: Manufacturers with high industry status and qualification often have certain advantages in product quality, technology research and development and enterprise management. For example, check whether the manufacturer has obtained international and domestic authoritative certifications such as ISO 9001 quality management system certification and CE certification. These certifications are a recognition of the product quality and production management level of the enterprise. At the same time, paying attention to the membership of manufacturers in trade associations and the honorary awards they have won can also be used as a reference for evaluating their credibility and reputation.

Cooperation cases and customer groups: Knowing the cooperation cases and customer groups of manufacturers can intuitively understand the application of their products in different industries and enterprises. If the manufacturer has established long-term cooperative relations with many well-known enterprises and has a wide range of application cases in various industries, it shows that its product quality and service level have been recognized by the market. You can ask the manufacturer for a list of cooperation cases and try to contact some customers for on-the-spot investigation or consultation.

Evaluate product quality: Ensure the excellent performance of profile bending machine.

Stability and durability of the equipment: The machine à plier les profilés needs to maintain stable performance and reliable operation during long-term use. Choosing a profile bending machine with reasonable structure, exquisite manufacturing technology and high-quality materials and parts can effectively improve the stability and durability of equipment, reduce the number of equipment failures and maintenance, and reduce the operating costs of enterprises. For example, a high-quality profile bending machine can maintain uniform rolling force and speed in the rolling process, and avoid quality problems such as uneven deformation and surface scratch of the profile.

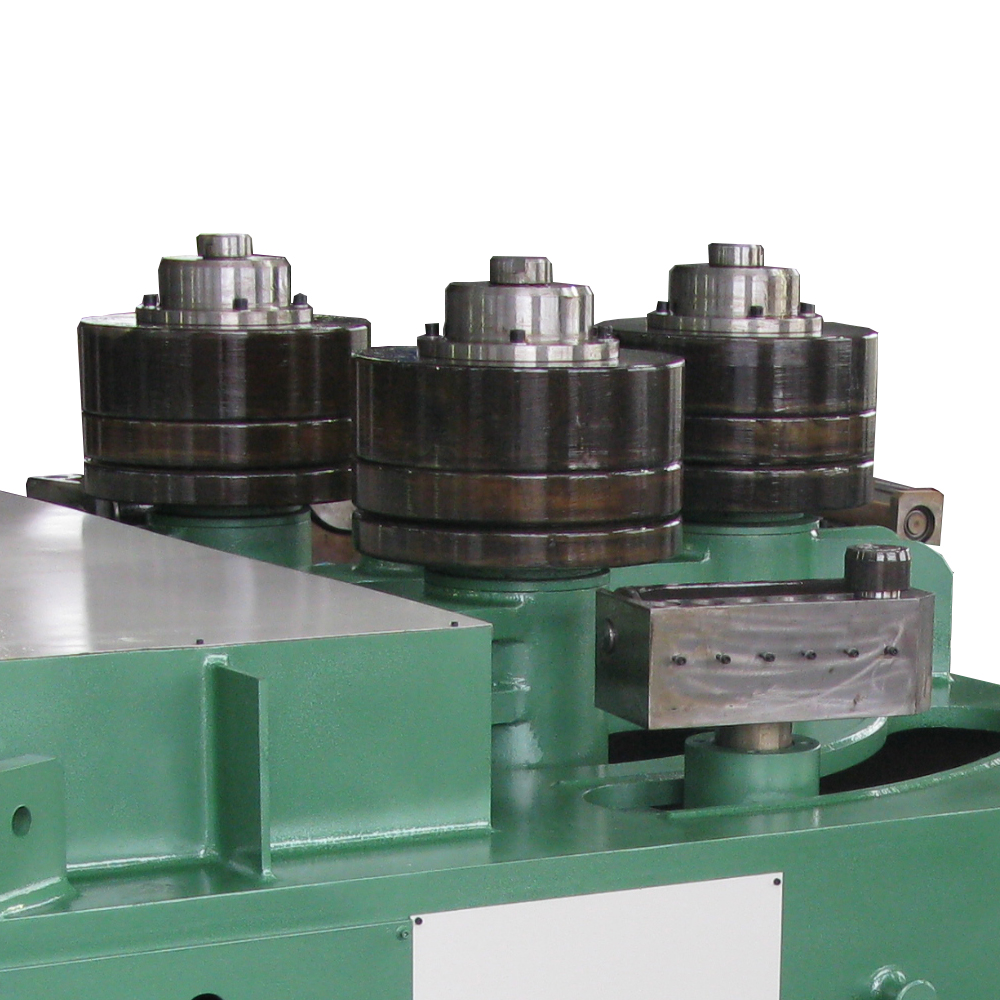

Quality of core components: The core components of profile bending machine, such as roller shaft, reducer, motor and control system, directly affect the performance and service life of the equipment. When selecting the profile bending machine, you should know the brand, model, quality and performance of the core components in detail. For example, well-known brands of motors and reducers have higher efficiency and reliability, and advanced control systems can achieve more accurate operation and control, thus improving the overall performance of the profile bending machine.

Quality inspection and control: Understanding the manufacturer’s quality inspection and control system is an important link to ensure product quality. Excellent manufacturers usually establish perfect quality inspection processes and standards, and carry out strict quality inspection and control in every link, from raw material procurement, parts processing to equipment assembly and debugging. Manufacturers may be required to provide quality inspection reports and relevant certificates to prove that their products meet quality standards.

Pay attention to technological innovation ability: adapt to the trend of industry development.

R&D investment and innovation achievements: Investigate the investment and innovation achievements of manufacturers in technology research and development. Manufacturers with strong technological innovation capabilities will continuously introduce new products, technologies and new processes to meet the needs of the market and customers. For example, some advanced profile bending machines adopt numerical control technology, servo drive technology, intelligent control technology, etc., which realizes automatic and intelligent production and improves production efficiency and product quality. You can pay attention to the manufacturer’s official website, news media reports, etc., to understand its latest research and development achievements and technological innovation trends.

Cooperation with universities and scientific research institutions: Cooperation with universities and scientific research institutions is an important way for manufacturers to obtain cutting-edge technologies and innovative resources. Through the cooperation of Industry-University-Research, manufacturers can transform the scientific research achievements of universities and scientific research institutions into actual productivity, and at the same time, they can also use the talent advantages of universities and scientific research institutions to enhance the technological research and development level and innovation ability of enterprises. When selecting the manufacturer of profile bending machine, we can know whether it has established cooperative relations with universities and scientific research institutions, as well as cooperative projects and achievements.

Product upgrading ability: With the continuous development of the metalworking industry and technical progress, the technology and performance of profile bending machines are also constantly upgrading. Choosing a manufacturer with strong product upgrading ability can ensure that enterprises can obtain more advanced and efficient profile bending equipment in time in the future production process to adapt to the changes in the market and the needs of their own development.

Review after-sales service: Guarantee the long-term use of metal profile bending machine.

Installation, debugging and training services: Whether the manufacturer can provide professional installation and debugging services and operator training in time after purchasing the profile bending machine is directly related to whether the equipment can be put into use quickly and run normally. Excellent manufacturers usually send professional technicians to the customer’s site to install and debug the equipment, and provide customers with comprehensive operation training, including the operation process, maintenance methods and common troubleshooting of the equipment, so as to ensure that the customer’s operators can master the skills of using and maintaining the equipment skillfully.

Maintenance and spare parts supply: In the process of equipment use, faults and parts will inevitably be damaged. At this time, it is particularly important for manufacturers to provide timely maintenance services and adequate supply of spare parts. Choosing a manufacturer with perfect after-sales service network and quick response mechanism can get timely maintenance and replacement of parts when the equipment fails, reduce the downtime of equipment and reduce the losses of enterprises. You can know the manufacturer’s after-sales service telephone number, maintenance site distribution, spare parts inventory, etc., so as to evaluate its maintenance and spare parts supply capacity.

Warranty period and service commitment: Knowing the warranty period and service commitment provided by the manufacturer is an important indicator to evaluate its after-sales service quality. Generally speaking, the longer the warranty period, the more confident the manufacturer is about the quality of its products. At the same time, pay attention to the manufacturer’s service content and charging standards within and outside the warranty period, so as to ensure continuous high-quality service during the use of the equipment. The manufacturer may be required to specify the warranty period, service content and liability for breach of contract in the contract to protect the legitimate rights and interests of the enterprise.

Compare price with cost performance: realize the balance between cost and benefit.

Consideration of price factor: Price is one of the factors that enterprises will inevitably consider when choosing a profile bending machine manufacturer. When comparing the prices of different manufacturers, we should not only pay attention to the initial purchase price of equipment, but also consider the performance, quality and after-sales service of equipment. Sometimes, a slightly higher price profile bending machine may have more advantages in performance and quality, which can bring higher production efficiency and economic benefits to enterprises, but in the long run, it is more cost-effective. Therefore, according to the actual needs and budget of enterprises, we should choose a profile bending machine with reasonable price.

Evaluation of cost performance: Cost performance refers to the ratio between comprehensive factors such as equipment performance, quality and after-sales service and the price. When evaluating the price/performance ratio of profile bending machine, we can use scoring method and weighted average method to comprehensively evaluate the equipment of different manufacturers. For example, we can set several evaluation indexes such as equipment performance, quality, after-sales service and price, and set corresponding weights for each index, then score each manufacturer’s equipment according to the actual situation, and finally calculate the comprehensive score of each manufacturer. The higher the score, the higher the cost performance. Through this method, we can evaluate the cost performance of different profile benders more objectively and comprehensively, and provide scientific basis for enterprise decision-making.

Cost-benefit analysis: When selecting the manufacturer of profile bending machine, cost-benefit analysis is also needed. In addition to the purchase cost of equipment, it is also necessary to consider the influence of equipment operating cost, maintenance cost, energy consumption, production efficiency, product quality and other factors on the economic benefits of enterprises. For example, a high-efficiency, energy-saving and low-maintenance profile bending machine can save a lot of operating costs and improve production efficiency for enterprises in the long-term use process, which will bring higher economic benefits. Therefore, from the perspective of cost-effectiveness, we should choose the manufacturer of profile bending machine that is most suitable for the development of enterprises.

Field inspection: The importance of seeing is believing.

On-site inspection: On-site inspection of the production site of the profile bending machine manufacturer can intuitively understand its production scale, production equipment, production technology and quality management. Observing the cleanliness of the production site, the advanced level of equipment, the proficiency of workers, etc., can give a preliminary judgment on the overall strength and production level of the manufacturer. At the same time, you can also check the storage and management of raw materials, the processing accuracy and quality of parts, and further understand the quality control of their products.

Equipment demonstration and testing: During the field investigation, it is the most direct way to know the performance and quality of the equipment by asking the manufacturer to demonstrate and test its profile bending machine equipment on the spot. By observing the rolling process, operation flow and control accuracy of the profile bending machine on the spot, we can have a deeper understanding of the performance and quality of the equipment. At the same time, you can also operate the equipment yourself and feel the convenience and comfort of the equipment. In the process of equipment demonstration and testing, we should pay attention to the parameters such as operation stability, rolling accuracy and noise level of the equipment, as well as the performance of the equipment under different working conditions.

Face-to-face communication with the manufacturer: Face-to-face communication with the managers, technicians and sales staff of the profile bending machine manufacturer can help you to know more about the development strategy, technology research and development capability, product quality control and after-sales service of the enterprise. Through communication, we can know the importance of the manufacturer to the customer’s needs, the ability and attitude to solve problems, and so on, so as to judge whether it is a trustworthy partner. At the same time, we can also communicate and discuss with the manufacturers in depth on the specific needs and concerns of enterprises, and seek the best solution.

Conclusion: Choosing the right profile bending machine manufacturer is the key to success.

It is an important work that needs to be treated with caution to select a suitable profile bending machine manufacturer. Through the comprehensive evaluation and analysis of defining their own needs, investigating manufacturers’ reputation and reputation, evaluating product quality, paying attention to technological innovation ability, examining after-sales service, comparing prices and cost performance, and on-the-spot investigation, enterprises can choose the most suitable profile bending machine manufacturer and provide reliable equipment support and guarantee for their production activities. In today’s highly competitive market environment, only by choosing a suitable profile bending machine manufacturer can we improve the production efficiency, product quality and economic benefits of enterprises, and thus remain invincible in the market competition. I hope that the introduction and suggestions in this paper can be helpful to the majority of enterprises in selecting profile bending machine manufacturers, and I wish everyone can find an ideal partner to realize the sustainable development of enterprises.