Working Principle of 2 Rolls Plate Rolling Machine

Working principle of 2 rolls plate rolling machine: The upper roller of the plate bending machine is at a symmetrical position in the center of the two lower rollers. The hydraulic oil in the hydraulic cylinder acts on the piston to perform vertical lifting and lowering movements. The final gear of the main reducer drives the gears of the two lower rollers to mesh and rotate to provide torque for the rolled plate. The flat plastic metal plate of the plate rolling machine passes between the three working rollers (two lower rollers and one upper roller) of the equipment. With the help of the downward pressure of the upper roller and the rotational movement of the lower roller, the metal plate is continuously bent in multiple passes, resulting in permanent plastic deformation and roll into the required cylinder, cone or part thereof.

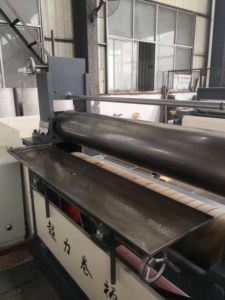

The two-roll plate rolling machine is a two-roller-to-roller plate rolling equipment. It is mainly used to bend metal plate cylindrical cylinders with a thickness of 0.5-5mm, a width of 300mm-2000mm, and a yield limit of less than 350Mpa during cold use. It is widely used in the production of various cylindrical cylinders in automobiles, food machinery, motors, fire-fighting equipment and other industries. The two-roller plate rolling machine is characterized by high product precision, no extra straight edges, and high production efficiency. The highest precision error is less than 0.5mm; the highest efficiency can reach 400 pieces/hour.

The steel plate is pressed between the upper roller (two rollers) and the lower roller (elastic roller) by the upper roller. The elastic layer of the lower roller forms a concave shape to urge the steel plate to bend, forming the curvature. According to the different structural forms and control means, the machine’s capabilities and efficiency are determined.

Features of 2 Rolls Plate Rolling Machine

High-efficiency rolling: The 2-roll plate rolling machine adopts a high-speed ratio K series reducer and small power motor matching, realizing big torque and energy saving at the same time, the finished roundness of rolled products is high and the diameter error is ≤4‰.

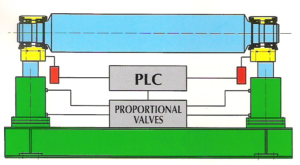

Automatic leveling: automatic leveling technology on both sides of the roll axis solves the problems of manual adjustment and the wrong edge of finished products, which greatly improves working efficiency.

Hydraulic tipping frame: equipped with a hydraulic tipping frame, saving labor and improving operation efficiency, making the rolled workpiece more relaxed.

Intelligent control: Equipped with Siemens PLC and a touch screen, it realizes freely programmed free-rolling, which is convenient for operation and improves production efficiency.

Multifunctional application: 2 rolls plate rolling machine is suitable for rolling round, arc, cone, square, multi-section arc-shaped workpieces in energy, transportation, petroleum, chemical, boiler, shipbuilding, hydropower, metal structure, and other industries.

Parameters

| Model | Yielding limit of sheet metal(Mpa) | Max rolling thickness(mm) | Max rolling width(mm) | Rolling speed(m/min) | Power of electric motor(kw) | Power of hydraulic station motor(kw) |

| W10-1×300 | 245 | 1 | 300 | 4.5 | 0.37 | 2.2 |

| W10-2×400 | 245 | 2 | 400 | 4.5 | 0.37 | 2.2 |

| W10-2×600 | 245 | 2 | 600 | 4.5 | 0.55 | 2.2 |

| W10-3×700 | 245 | 3 | 700 | 4.5 | 0.75 | 3 |

| W10-3×800 | 245 | 3 | 800 | 4.5 | 0.75 | 3 |

| W10-3×1000 | 245 | 3 | 1000 | 4.5 | 1.1 | 3 |

| W10-3×1250 | 245 | 3 | 1250 | 4.5 | 1.1 | 3 |

| W10-4×1300 | 245 | 4 | 1300 | 4.5 | 1.1 | 3 |

| W10-4×1500 | 245 | 4 | 1500 | 4 | 1.5 | 3 |

| W10-3×1800 | 245 | 3 | 1800 | 4 | 1.5 | 3 |

| W10-3×2000 | 245 | 3 | 2000 | 4 | 1.5 | 3 |

Details of 2 Rolls Plate Rolling Machine

Environmental protection and energy saving: Adopting high speed ratio K series reducer and small power motor to realize large torque and energy saving at the same time.

Automatic Rolling: Configured with Siemens PLC and touch screen to realize freely programmable rolling for easy operation.

Pusher system: pusher system, is convenient for picking up materials and saving time.

Support system: with a support system for large cylinder support, improve product roundness.

Automatic leveling: with roller position monitoring and automatic leveling system to ensure product quality and stability.

hydraulic tipping stand: with hydraulic tipping stand, saving labor and improving efficiency.

Adjustable feeding platform: with an adjustable feeding platform, convenient for feeding.

Applications of 2 Rolls Plate Rolling Machine

● LNG vehicle bottles

● Ventilation duct industry

● Filter industry

● Pump industry

● Fire extinguisher industry

● Pressure vessel industry

● Automotive exhaust industry

● LPG pressure vessel industry