Macchina per il taglio laser

Macchina per il taglio laser

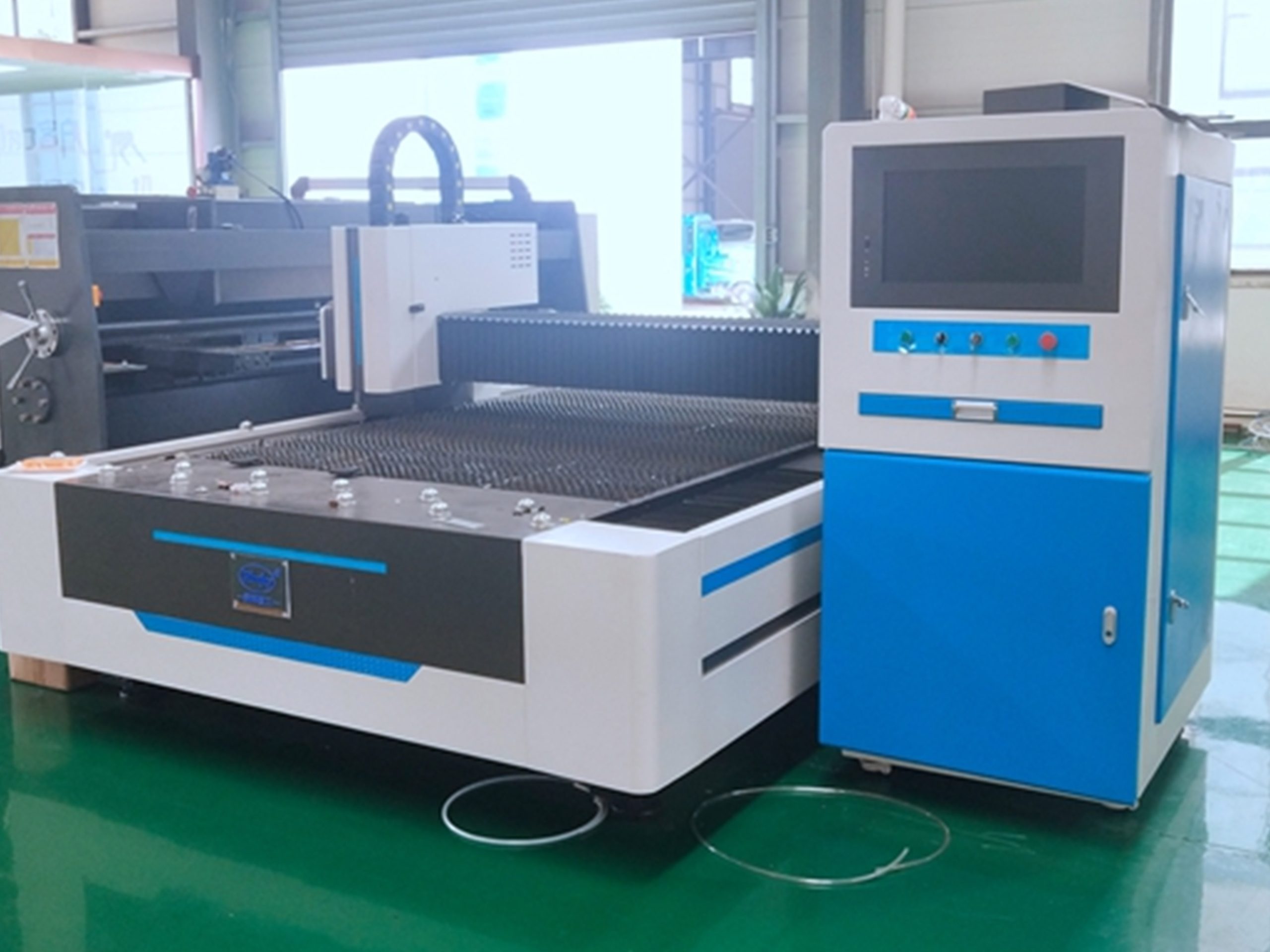

Product Overview

Laser cutting machines are high-tech tools that utilize a laser beam to cut materials. They are popular in industries such as metalworking, automotive manufacturing and electronics for their fast cutting speeds and high precision. They work perfectly with many types of materials.

Main Features

Efficient Ctting Capability:Laser cutting machines can cut much faster than older cutting machines. They can produce complex shapes quickly, thus increasing your production capacity. This fast cutting ability saves businesses time and money when making large quantities of items.

Multi-material Adaptability:The versatility of a Laser cutting machine is reflected in its ability to adapt to different materials. Whether it’s highly reflective metals such as copper and aluminum, or stainless and carbon steel of a certain thickness, Laser cutting machines provide an effective cutting solution.

Automated Operation: The integrated CNC system supports an automated process from design to cutting, reducing manual intervention, lowering error rates and increasing efficiency through automatic loading and unloading systems, auto-focus and real-time monitoring.

Dual Drive System: Provides more power and more stable running performance, especially suitable for mass production and complex graphic cutting needs.

Safety Protection:Laser cutting machine is equipped with multiple safety measures, including laser radiation shield, emergency stop button and safety door locking system to ensure the safety of operators. In addition, the machine can be equipped with a smoke and gas filtration system to protect the operator from harmful gases and dust.

Flexible Programming Capabilities:Laser cutting machines support integration with a wide range of CAD/CAM software to speed up the transition from design to production. Users can import cutting patterns directly from the design software, quickly adjust parameters and begin cutting immediately, greatly reducing the time from design to finished product.

Maintenance and Energy Consumption

Laser Cutting Machine Maintenance

The smooth and safe operation of a Laser cutting machine requires regular maintenance and in-depth inspection. Routine maintenance includes organizing and cleaning glass parts and ensuring that the cooling and air systems are functioning well. Regular maintenance includes lubricating the rails, checking the seals of the components, the health of the laser, and how the machine is mounted. It also includes deep cleaning and inspection of moving parts, electrical components and software every six months or a year. Professional care means thorough inspections, performance tests and the use of restoration assistance from the manufacturer.

Proper use of equipment requires that workers know how to operate it, wear protective equipment correctly and follow safety procedures. These measures help improve equipment durability, workplace safety and productivity.

Optimizing Energy Consumption

To reduce the energy consumption of a Laser cutting machine, you can take the following steps, choose a laser that uses less energy, such as a fiber laser. Use power saving mode and turn off the power promptly when the machine is idle. Adjust cutting setting parameters to reduce waste. Reasonable layout of equipment to reduce overall energy consumption. Perform regular maintenance on equipment to ensure it is in optimal working condition. Use energy-saving accessories, such as high-efficiency motors and lighting systems. Make cutting paths smarter with the help of computers and educate workers to conserve energy. All of this will result in machines that are cheaper to run, better for the planet and last longer.

PRODUCT CATEGORY

È il momento di contattare

CONTATTATECI

Pronjas vi offre un servizio di consulenza pre-vendita gratuito e dettagliato. Se desiderate maggiori informazioni su di noi, saremo lieti di fornirvele.

- +86-13606279128

- ntcljbj@hotmail.com

- +86-13606279128

- No.111 Tonghai Road, Libao Town Industrial Zone, Hai'an, Nantong, Jiangsu Province, China