Introduction

This series of 3 Rolls Hydraulic Plate Rolling Machine is suitable for making cylindrical, circular, conical and other metal plate molding needs,widely used in construction machinery, conveyor drums, concrete mixer trucks and other fields. There are generally three models in this series:

W11S series

The W11S series upper roller can move vertically and horizontally. The lower roller cannot move in any way, only rotates. Without pre bending function, pre bending is achieved by moving the upper roller horizontally, causing the upper roller to be in an asymmetric position relative to the lower roller. During the rolling process, the two lower rollers are driven by an electric motor and a reducer, and the flipping frame adopts hydraulic flipping. The vertical displacement of the upper roller adopts hydraulic transmission, and the horizontal movement adopts mechanical transmission.

The W11S series upper roller can move vertically and horizontally. The lower roller cannot move in any way, only rotates. Without pre bending function, pre bending is achieved by moving the upper roller horizontally, causing the upper roller to be in an asymmetric position relative to the lower roller. During the rolling process, the two lower rollers are driven by an electric motor and a reducer, and the flipping frame adopts hydraulic flipping. The vertical displacement of the upper roller adopts hydraulic transmission, and the horizontal movement adopts mechanical transmission.

W11Y series

The W11Y series upper roller can only move vertically and cannot move horizontally. The lower roller cannot move in any way, only rotates. Not equipped with pre bending function. During the rolling process, the two lower rollers are driven by an electric motor and a reducer, and the flipping frame adopts hydraulic flipping. The vertical displacement of the upper roller adopts hydraulic transmission.

W11X series

The W11X series upper roller can only move vertically and cannot move horizontally. The two lower rollers can move horizontally separately, achieving adjustable center distance. The smaller the center distance during rolling, the better the roundness; The larger the center distance during calibration, the greater the ability. During rolling, both the upper and lower rollers are powered by hydraulic motors. The horizontal movement of the lower roller adopts hydraulic transmission.

A. Forged parts constitute the transmission structure, durable and reliable.

B. Forged solid roller shaft with high standard heat treatment process.

C. YZR lifting motor and ZSY hardened gear reducer ensure stability and durability.

D. Using zinc-based alloy material for transmission parts, the durability is increased by 5 times.

E. Imported brand seals, such as NOK, are used to ensure sealing performance.

Features of 3 Rolls Hydraulic Plate Rolling Machine

Enhanced cone winding device, the whole unit is welded to the base, which is stable and durable. Gears and other components are all forged parts.

Equipped with full set of Siemens electrical components, including PLC and touch screen, with wireless operating handle. Forge solid roller shaft and undergo high standard heat treatment process.

Absolute encoder scale is used for automatic zeroing to ensure the roll ends are parallel and improve accuracy. Large and medium-sized models use YZR lifting motors to ensure the stability of the instantaneous current during startup. And it adopts ZSY hard tooth reducer, providing high torque and durability. Transmission components such as worm gears and nuts made of zinc based alloy materials are used instead of casting materials, resulting in a 5-fold increase in durability.

Self-developed and self-made high-quality hydraulic system with high stability and low oil leakage rate. Medium and large-sized models use forged cylinder bodies, and imported brands such as NOK are selected for sealing rings.

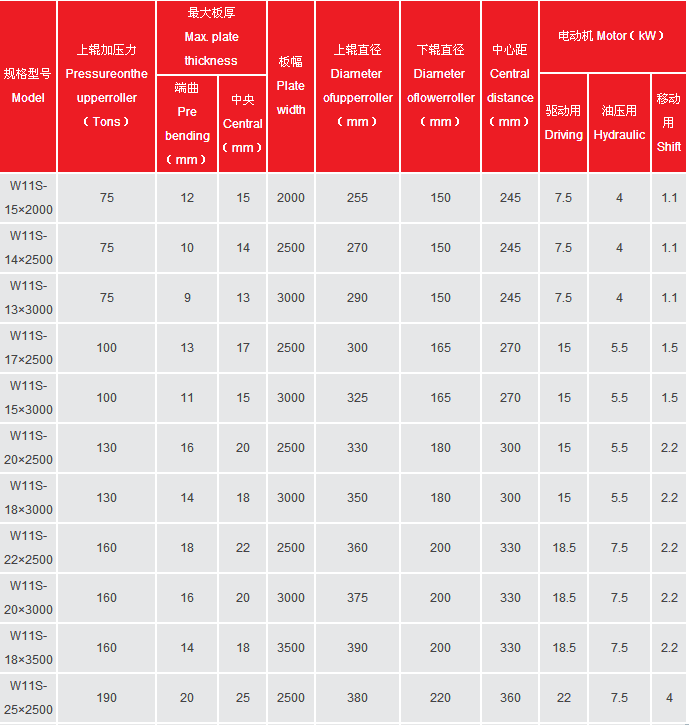

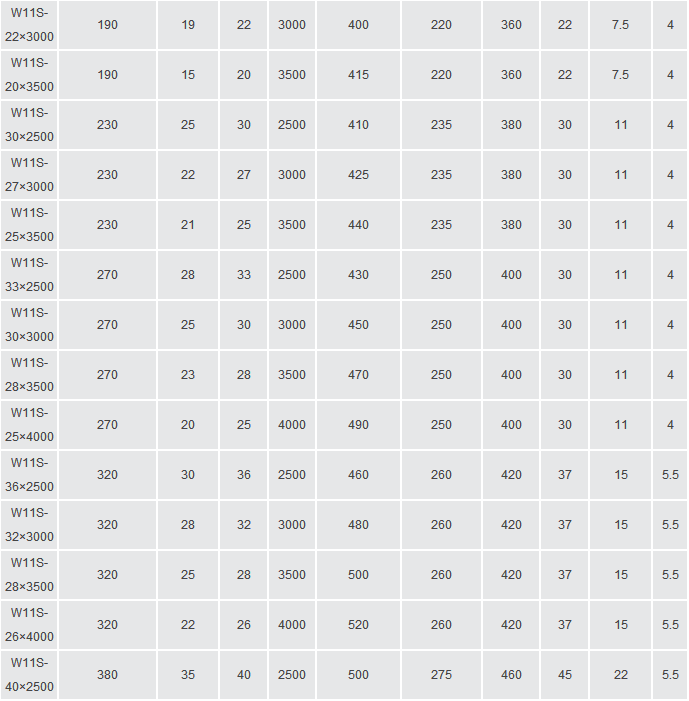

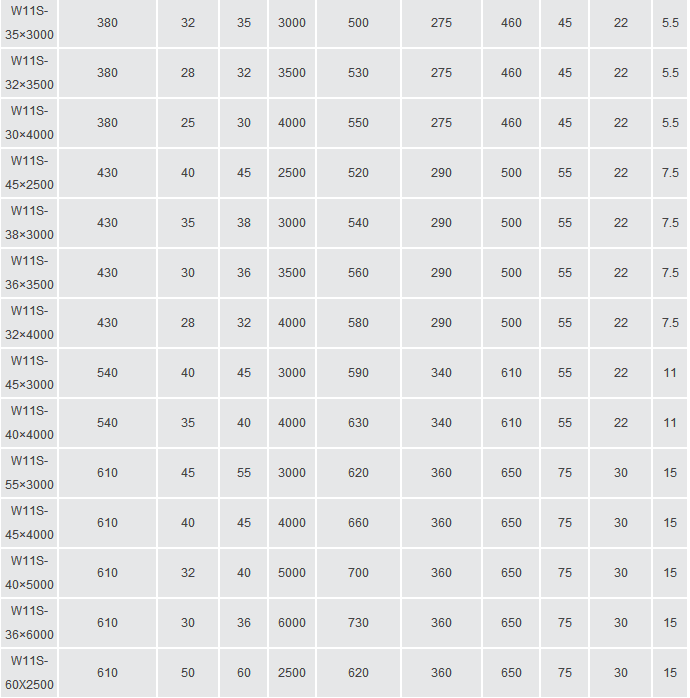

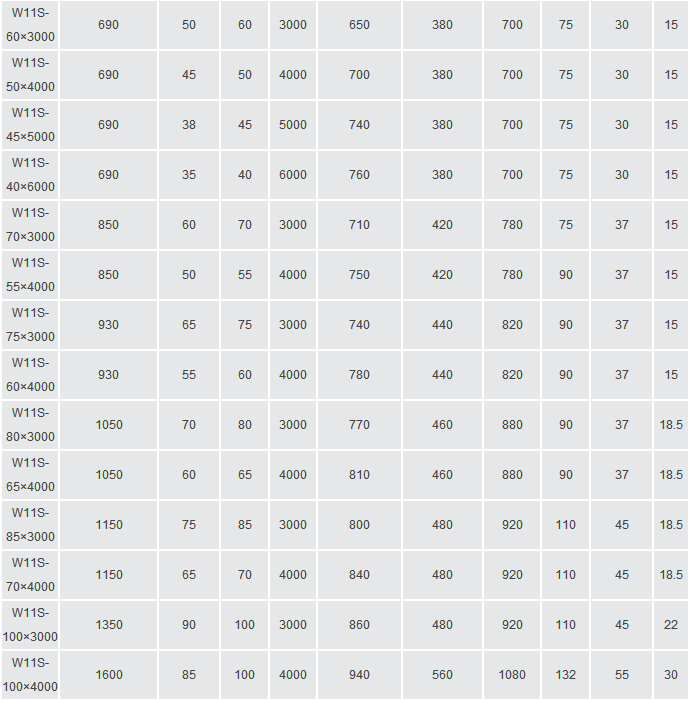

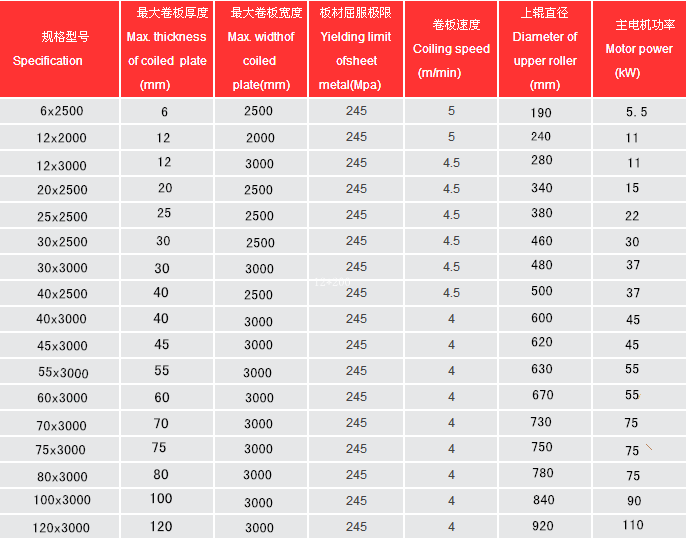

Technical Parameters

W11S series: with pre-bending function, suitable for small, medium and large full range of product specifications.

W11Y series: without pre-bending function, can only realize the vertical movement of the upper roller, suitable for larger plate thickness.

Standard features include solid rollers for flaw detection, roller tempering treatment, roller surface hardening treatment, digital readout, high quality hydraulic system and so on.

Details of 3 Rolls Hydraulic Plate Rolling Machine

Enhanced cone rolling device, welded to the base as a whole, with one pair on both sides, sturdy and durable.

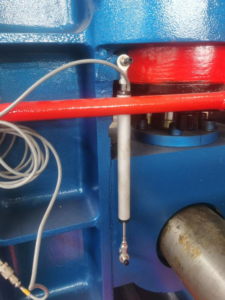

Complete set of Siemens electrical components including PLC and touch screen, equipped with wireless operating handle. Equipped with an absolute value encoder ruler, it is more durable compared to ordinary rope encoders and has an automatic zeroing function to prevent data errors from accumulating and causing the two ends of the roller shaft to be not parallel.

Self developed and self manufactured high-quality hydraulic system with high stability and low oil leakage rate.

Applications of 3 Rolls Hydraulic Plate Rolling Machine

-

Construction machinery (trenchers)

Hydraulic three-roll plate winder plays a key role in the manufacture of trenchers. Trenchers usually require a large number ofmetal components to support and fix various parts, hydraulic three-roller plate winder can roll metal sheets into cylindrical or conical components of the required diameter to meet the various structural requirements of trenchers. Its precise rolling capacity and stable performance ensure the structural stability and working reliability of trenchers.

-

Construction machinery (road rollers)

Hydraulic three-roll coiler plays an important role in the manufacture of road rollers. Road rollers require large metal cylinders to support the weight of the roller with good strength and durability. With the hydraulic three rollcoiler, sheet metal can be rolled into cylinders of the required diameter to provide a strong support structure for the rollers. Its efficient rolling speed and reliable rolling quality guarantee the construction efficiency and service life of the roller.

- Conveyor Roller

Conveyor rollers are usually used in material conveying systems and need to have good wear resistance and strength. Hydraulic three-roller rollers can roll metal sheets into cylindrical drums of required diameter to support conveyor belts in the conveying system and realize smooth material conveying. Its high-quality hydraulic system and precise rolling capability ensure stable operation and long-term reliability of the conveyor drum.

- Concrete mixer trucks

Concrete mixer trucks usually need to have strong mixing capacity and stable structure. Hydraulic three-roller plate rolling machine can roll metal plates into the shape of mixing cylinder, which ensures themixing effect and structural stability of concrete mixer trucks. Its precise rolling capacity and efficient working speed ensure the productivity and quality of concrete mixer trucks.

-

Bridge shield

Bridge shields usually need to have good resistance to pressure and corrosion. Hydraulic three-roll coiler can roll metal sheets into required diameter and thickness of sheathing barrels for bridge support and protection. Its high-quality hydraulic system and precise rolling technology ensure the stability and durability of the sheathing barrels, which provides a reliable guarantee for the safe operation of bridges.

-

LNG Gas Tanks

The hydraulic three-roll coiler can roll metal sheets into the cylindrical structure required for LNG gas tanks, which has good sealing and pressure-resistant performance, ensuring the safeoperation of LNG gas tanks. Its high-precision rolling capacity and reliable performance ensure the stability and sealing of the gas tanks, providing a reliable guarantee for the storage and transportation of LNG.