Introduction

With the rapid development of manufacturing industry, metal profile bending machine has become an indispensable key equipment in many fields. Whether it is exquisite modeling in architectural decoration or precision components in aerospace field, it is inseparable from its “carving”. Facing the dazzling array of metal profile bending machines in the market, it is undoubtedly an important step for enterprises to choose a device that meets their own needs. This is not only related to production efficiency and product quality, but also closely related to cost control and market competitiveness. Next, let’s explore the mystery together.

The basic cognition of metal profile bending machine

The core definition and function

Simply put, the metal profile bending machine is a kind of mechanical equipment specially used for accurately bending all kinds of metal profiles at a predetermined angle. Like a skilled craftsman, it takes strong mechanical force as the “hand” and precise control system as the “eye” to shape straight metal profiles into various complex and practical shapes, laying the foundation for subsequent product assembly and processing.

Overview of common types

W24 Vertical CNC Profile Bending Machine

A W24 Vertical CNC Profile Bending Machine supported by numerical control, just like a precision instrument. It can bend complex profiles with high accuracy by using vertical force and advanced CNC programming control, and is often used in aerospace, high-end electronic equipment housings and other fields that require almost strict dimensional tolerance.

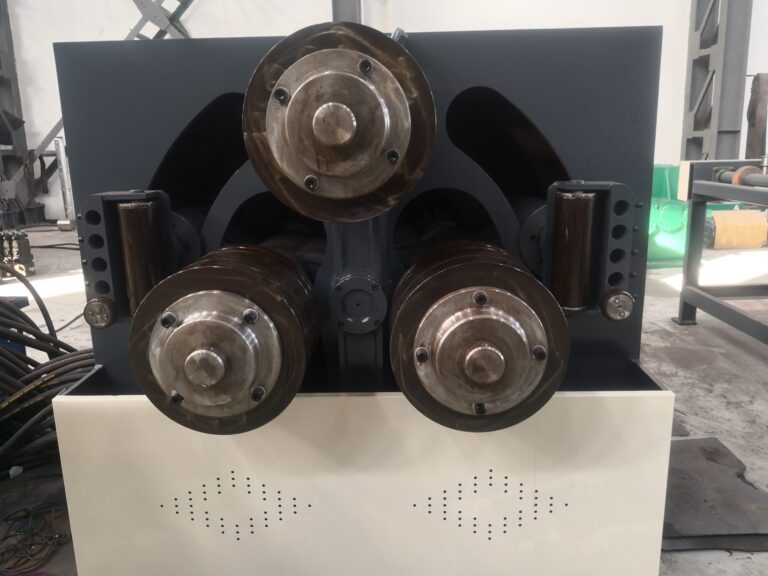

W24 2-roll profile bending machine

With the double-roll structure, W24 2-roll profile bending machine performs well in some small-scale machining scenes that require relatively moderate precision but pay attention to continuous machining efficiency. Through the cooperation of two rotating rollers, it gently and stably pushes the profile to bend, which is suitable for batch bending of profiles with smaller diameters or narrow edges.

W24S horizontal profile bending machine

The horizontal layout makes W24S horizontal profile bending machine unique in operation convenience and large profile processing. Operators can observe the bending process more intuitively, handle the bending of long-sized and heavy metal profiles with ease, and are widely used in shipbuilding, large-scale mechanical frame construction and other industries.

W24S Hydraulic Metal Profile Bending Machine

Hydraulic drive gives it powerful and stable power. In the face of high-strength and thick-walled metal profiles, W24S Hydraulic Metal Profile Bending Machine can easily exert enough bending force to ensure the accurate molding of profiles, and is a right-hand man in the fields of steel structure processing, bridge engineering and so on.

Machining accuracy requirements of key factors

The accuracy of different industries benchmark

Aerospace: In this field of pursuing ultimate performance and safety, the bending accuracy of metal profiles needs to reach micron level. For example, even a slight bending deviation of the supporting profile of an airplane wing may affect the flight stability. Therefore, it is necessary to rely on high-precision numerical control equipment such as W24 Vertical CNC Profile Bending Machine, and cooperate with a precise die system to ensure that every bending is accurate.

Architectural decoration: Relatively speaking, the accuracy requirement is a little loose, but aesthetics is equally important. Most of the design requirements can be met by controlling the bending error of door and window frame profiles in millimeter level. At this time, economical equipment such as W24 2-roll profile bending machine can give full play to the cost advantage and complete the task efficiently.

Components and technologies that affect accuracy

Bending die: high-quality die is the cornerstone of accuracy. The die made of high-strength alloy steel and finely ground can closely fit the profile, reduce springback and ensure accurate bending angle.

Guide system: the combination of high-precision guide rail and slider is like installing a “track” for the machine, which ensures that the upper and lower dies are always vertically aligned during the bending process, avoiding lateral deviation and escorting stable precision output.

Control system: advanced CNC system or intelligent electronic control unit can accurately control the speed, strength and angle of bending and adjust the processing parameters in real time to cope with the changes of different profiles’ materials and shapes, which is the brain center to realize high-precision processing.

The key points of choice to adapt to the production scale

The weapon of mass production

For large-scale mass production enterprises, such as auto parts manufacturers, the efficiency and stability of equipment are very important. With its rapid die changing system, high-speed bending ability and reliable mechanical structure, W24S horizontal profile bending machine can realize assembly line operation, greatly shorten the processing time of single piece and meet the demand of high output.

The flexible choice of small batch customization

Flexibility becomes the key when facing the business with high customization and small orders, such as high-end art decoration processing. Equipment such as W24 2-roll profile bending machine, which is relatively simple to operate and convenient to debug, can quickly adapt to the frequent switching of different profile specifications and bending requirements, reduce the idle time of the equipment and reduce the cost.

Adaptability of profile material and bending machine

The characteristics of common metal profiles

Aluminum alloy: light weight, corrosion resistance, widely used in aviation and electronics. However, its hardness is relatively low, so attention should be paid to control the bending strength to prevent excessive deformation, and it is suitable for matching with hydraulic or numerical control bending machines with flexible control functions, such as W24S Hydraulic Metal Profile Bending Machine.

Carbon steel: It has high strength and low cost, and is often used in construction and machinery manufacturing. However, due to its material characteristics, the bending process is prone to cracks, which requires the bending machine to have powerful power and accurate stress control. A high-power drive like W24S horizontal profile bending machine can meet the demand.

Stainless steel: both beautiful and corrosion-resistant, it is favored in kitchen utensils, medical devices and other industries. However, its work hardening phenomenon is obvious, which causes great wear to the die of the bending machine. Therefore, it is necessary to choose the die with good wear resistance and the equipment that can finely adjust the processing parameters, such as W24 Vertical CNC Profile Bending Machine.

Special requirements of materials for equipment

Auxiliary heating function: For some high-strength alloy or thick-walled profiles, it is difficult to bend at room temperature. The bending machine equipped with heating device can soften the profiles at a suitable temperature, reduce the bending difficulty and improve the molding quality.

Stress relief technology: Residual stress will be generated after metal bending, and long-term accumulation may lead to deformation or cracking of profiles. Advanced bending machines should be equipped with stress relief processes, such as vibration aging or thermal aging treatment, to ensure the long-term stability of products.

The convenience of operation and personnel training costs

Humanized design to improve efficiency

Intuitive operation interface: Modern bending machine adopts touch-screen CNC control system, which is illustrated with pictures and texts. Operators can get started quickly with simple training, such as the control system of W24S series equipment, which simplifies complex programming instructions into visual icon operation.

Convenient die changing device: The rapid die changing system can greatly shorten the downtime of equipment and reduce the intensity of manual operation. Some high-end models even realize automatic mold changing, and the mold can be accurately positioned with one-click operation, which greatly improves the production efficiency.

Personnel training considerations

For complex CNC bending machines, such as W24 Vertical CNC Profile Bending Machine, although powerful, operators need to have certain knowledge of CNC programming and mechanical principles, and enterprises need to invest more time and cost in training.

The relatively simple 2-roll bending machine has a short training period, and novices can master the basic operation quickly, which is suitable for small enterprises with frequent personnel turnover or weak technical strength.

The importance of equipment maintenance and after-sales support

The main points of daily maintenance

Maintenance of mechanical parts: Regularly check the wear of moving parts such as guide rail, slider and roller shaft, and add lubricating oil in time to ensure smooth operation of the equipment.

Maintenance of hydraulic system: For hydraulically driven bending machines, such as W24S Hydraulic Metal Profile Bending Machine, attention should be paid to the quality and level of hydraulic oil, and the filter should be replaced regularly to prevent hydraulic system failure.

Electrical system maintenance: Check whether the electrical components such as wires, plugs and controllers are normal, so as to avoid equipment downtime or misoperation due to electrical problems.

After-sales guarantee

Quick-response technical support: When the equipment breaks down, it is very important to get the technical guidance and maintenance service from the manufacturer in time. High-quality manufacturers usually provide 24-hour hotline support to ensure that problems can be solved in the shortest time.

Adequate spare parts supply: timely supply of common spare parts can greatly shorten the equipment maintenance time. Reliable suppliers will set up spare parts warehouses in various places to ensure that faulty parts can be replaced quickly in an emergency and reduce production losses.

Comprehensive cost-benefit analysis

Procurement cost comparison

The prices of different types and brands of metal profile bending machines are quite different. The basic W24 2-roll profile bending machine is affordable and suitable for start-ups with limited budget. The high-end W24 Vertical CNC Profile Bending Machine is relatively expensive because of its integration of advanced technology and precision components, but it can bring higher production added value.

Operating costs considerations

Energy consumption: Compared with electric drive, hydraulic drive equipment consumes more energy in operation. After long-term use, the energy cost should not be underestimated, and enterprises need to choose according to their own energy cost structure.

Mold cost: The mold with high precision and complex shape has high manufacturing cost and limited service life. When choosing a bending machine, we should consider its universality and loss to the mold, and try to choose equipment that can reduce the cost of the mold.

Evaluation of return on investment

Considering the production efficiency of equipment, the market benefits brought by the improvement of product quality and the reduction of operating costs, the return on investment is calculated. For example, an efficient W24S horizontal profile bending machine, though expensive to purchase, can recover its cost and make a profit in a short time through rapid mass production and high-quality products.

Case study: successful selection practice in different industries

Aerospace field

A well-known aviation component manufacturer chose a W24 Vertical CNC Profile Bending Machine manufacturer to meet the high-precision bending requirements of new aircraft wing profiles. Through the CNC system seamlessly connected with the design software, the complex airfoil profile can be accurately bent at one time, and the rejection rate is reduced to almost zero, which greatly improves the production efficiency and ensures the aircraft performance.

Building decoration industry

An enterprise specializing in the customization of high-end doors and windows, faced with diversified profile specifications and order requirements, adopted the scheme of matching W24 2-roll profile bending machine with W24S Horizontal Profile Bending Machine. The former is used for flexible processing of small-batch and special-shaped profiles, while the latter is responsible for mass production of standard profiles. Together, the two meet the individual needs of customers and ensure cost-effectiveness.

Shipbuilding enterprises

In the process of building large ships, the hull structure needs a lot of bending of high-strength carbon steel profiles. A shipbuilding enterprise introduced W24S Hydraulic Metal Profile Bending Machine. With its powerful hydraulic power and large-scale processing capacity, it efficiently completed the bending task of complex profiles, shortened the construction period and improved the quality of ships.

Conclusion

It is not easy to choose a suitable metal profile bending machine, which needs to comprehensively consider many factors such as processing accuracy, production scale, profile material, convenience of operation, after-sales maintenance and cost-effectiveness. Each equipment has its unique advantages and applicable scenarios. Only by deeply understanding its own needs and combining with the actual production situation can enterprises find the “golden key” that opens the door to efficient and high-quality metal processing among many choices.

Looking forward to the future, with the continuous progress of science and technology, the metal profile bending machine will develop in the direction of higher precision, intelligence and multifunction. If enterprises can keep up with the pace of the times and accurately select models, they will be in an invincible position in the fierce market competition and create a more brilliant future with exquisite metalworking technology.

It can meet your needs. If you have other ideas or suggestions on the structure, content and keyword integration of the article, please feel free to put forward them.