Plate Rolling Machine for Metal Pipe Manufacturing

Application Scenarios

The ventilation duct industry

Plate rolling machines are a great way to make the manufacturing of ventilation ducts more efficient. It allows for fast production in metal sheet bending, turning it into ducts with size control so as to maintain the uniformity that is necessary during their assembly and interconnection.

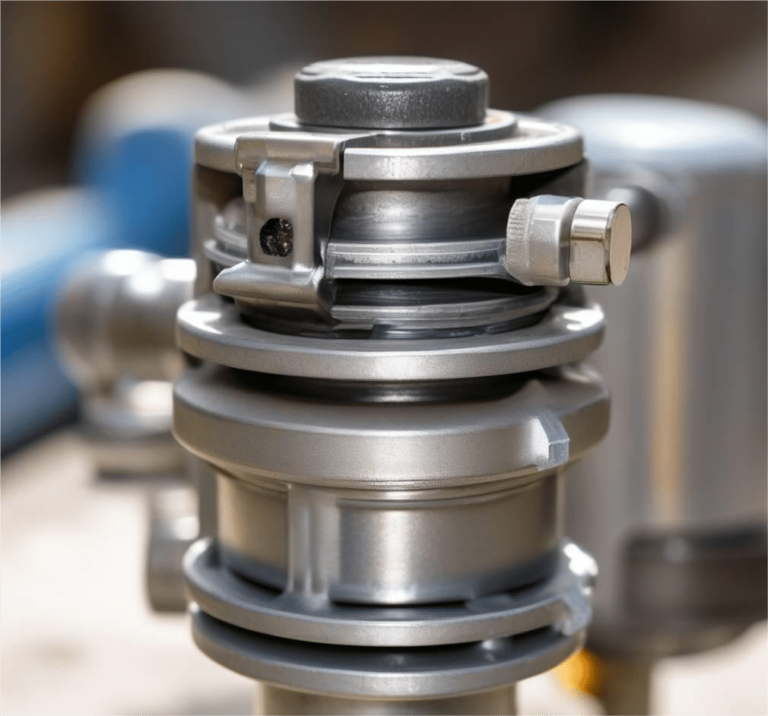

Pump industry

Plate rolling machines are essential for the production of plate. This enables them to suit the dimensions of pump casings and components perfectly. This makes it stronger and helps the pump stay functional as normal in a long-term. This is very handy in the case of pumps that are used with things like seawater for example since other materials can corrode.

LPG filter industry

Plate rolling machines are essential in the LPG Filter Business The filter parts they produce are extremely accurate, hold their shape well and withstand high temperatures and resistance.

Technical Advantages

Precise parameter adjustment

The plate rolling machine is capable of precisely adjusting the roll gap according to the thickness of the material, ensuring a smooth transition during the rolling process and avoiding material damage.

Intelligent control of temperature and lubrication

With the help of metal rolling machines, roll gaps and temperatures can be controlled to adjust bending radius as well as workability especially for hard materials.

Efficient Rolling Sequence Design

The design of metal rolling machine must consider the ability to absorb deformation with this material. It gradually directs the material to an appropriate target shape and size in proper sequence of rolling, ensuring processing quality.

Structural stability and durability

The structural design of the plate rolling machine ensures stability and durability during continuous operation, which reduces maintenance costs and improves productivity. Future developments: innovative trends in plate rolling machines

High Safety

Modern plate rolling machines are typically equipped with real-time monitoring systems that can promptly detect and respond to potential safety issues.

Adaptable material handling

The metal processing machine can adjust the rolling force and speed for materials with different hardness or strength, especially when working on hard material, brittle easily cracking at high speeds.

Future Developments

Automation and Intelligence

The future direction of metalworking machines will place greater emphasis on automation and intelligence. The integration of advanced sensors and intelligent control systems will enable the machines to automatically adjust rolling parameters and realize a higher degree of precise control and process monitoring.

Adaptability to new materials

With the continuous research and development of new materials, metal processing technology is upgraded to adapt to the processing needs of these new metal materials.

Environmental protection and energy saving

Environmental protection and energy savings are important considerations in the design of metalworking machinery. By optimizing design and processes, the plate rolling mills of the future will use energy more efficiently and reduce the environmental footprint of the production process.

Customization and Flexibility

Metalworking machinery will place greater emphasis on customization and flexibility to meet the individual needs of different industries and customers and to offer more diverse solutions.