Profile bending machine

Profile bending machine

With excellent performance and wide application, profile bending machine plays an important role in the industrial field, capable of accurately bending all kinds of metal profiles, such as angles, flats, squares, rounds and tubes, etc., to meet the bending needs of various accuracies. It is gradually becoming the ideal equipment for metal structure construction, shipbuilding and other industries.

Profile Bending Machine Application Scenario

1. Metal Structure Construction

Profile bending machines can easily manufacture various metal parts needed for construction that meet the accuracy requirements, improving the quality and speed of construction.

2. Shipbuilding

Profile bending machines are used to bend keels, ribs and deck beams for ship structures. These parts are critical components that ensure the stability and durability of the ship’s hull.

3. Aerospace

Profile bending machines are used to machine lightweight metal structural parts for aircraft and spacecraft, such as wing girders and fuselage frames. These high-precision bent parts are essential to ensure flight safety and performance.Machinery.

4. Manufacturing Industry

Profile bending machines are used to process machine brackets, conveyor belt brackets, mechanical arms and other components to improve the stability and efficiency of mechanical equipment.

Operating Instructions of Profile Bending Machine

In order to fully utilize the efficiency and versatility of a profile bending machine, it is important to understand its operating instructions. The following are the basic steps for operating profile bending machines:

1. Equipment Preparation

Before operating the profile bending machine, first you should ensure that the equipment is in good working order. Check the hydraulic system, electrical parts and transmission components for proper functioning and make sure all safety guards are in place.

2. Mold selection and installation

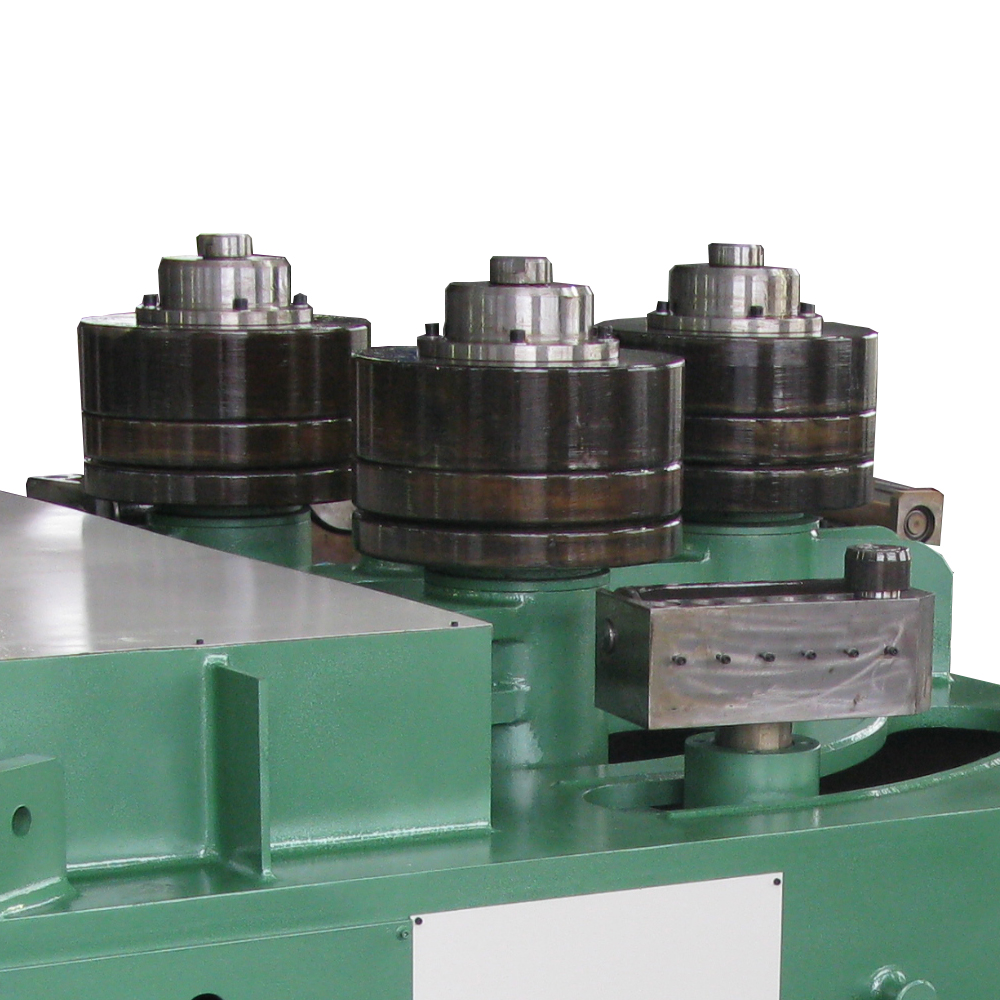

Depending on the type and size of the profile to be bent, the right mold is selected to ensure the effectiveness and quality of the bend. Our molds are meticulously crafted from top-grade 42CrMo alloy steel and then heat-treated for superior strength and durability. This guarantees effective bending and ensures that the molds can withstand heavy use.

3. Positioning and Adjustment of Profiles

The profile needs to be placed in the designated position on the bending machine and then fine-tuned using an adjustment tool to ensure that the profile is aligned with the rollers. Profile bending machines are equipped with automatic deflection side rollers that automatically correct the position of the profile during the bending process to maintain molding quality.

4. Precise control of the bending process

When the profile bending machine is turned on, the three main rolls move smoothly together thanks to the hydraulic system and gears. The right pressure and speed need to be set according to the type of metal and the degree of bending required. The operator keeps a close eye on the whole process to ensure that the settings are adjusted in order to ensure the quality and effectiveness of the bend.

5. Finishing and post-processing

Once the metal profile bending is complete, the machine is turned off. The necessary finishing touches are then applied, such as cutting to size, welding in place or giving a nice finish.

6. Precautions for safe operation

Safety should always be a priority throughout the entire operation. The operator should wear appropriate protective equipment such as safety helmet, protective glasses and gloves. Strictly follow the operating procedures and do not leave the console or allow non-operators to enter the work area while the machine is in operation.

FAQ

1. What is a profile bending machine?

A profile bending machine is a mechanical device specially designed for precisely bending profiles of metal or other materials. It can handle materials of various cross-sectional shapes, such as I-beams, H-beams, and U-beams.

2. What is the main function of a profile bending machine?

The main function of a profile bending machine is to precisely bend profiles at a specific bending radius and angle by applying pressure. The equipment is usually equipped with a CNC system, which makes the operation easier and more precise, and can meet complex design requirements.

3. What types of materials can a profile bending machine handle?

Profile bending machines can handle a variety of materials, including carbon steel, stainless steel, aluminum alloy, etc. Different machines may have different processing capabilities, so the type and specification of the material to be processed should be considered when choosing.

4. What are the application scenarios for profile bending machines?

Profile bending machines are widely used in multiple industries. They are often used for bending beams and columns in steel structure buildings, and are also used in the manufacture of large structures such as ships, bridges, and transmission towers. In addition, in the automotive industry, profile bending machines are also used to produce vehicle architectures and components. Welcome to know more.

5. How to choose a suitable profile bending machine?

When choosing a suitable profile bending machine, the following factors should be considered: material type and strength, required bending radius and angle, production efficiency and accuracy requirements, and the company’s budget. It is also very important to understand the technical parameters and after-sales service of the equipment to ensure the value of the investment. Welcome to know more about how to choose a suitable profile bending machine.

PRODUCT CATEGORY

It's time to contact

GET IN TOUCH

Pronjas offers you a free and detailed pre-sales consultation service. If you would like to see more information about us, we will be glad to provide it.

- +86-13606279128

- ntcljbj@hotmail.com

- +86-13606279128

- No.111 Tonghai Road, Libao Town Industrial Zone, Hai’an, Nantong, Jiangsu Province, China